Page 36 - Tạp chí bonsai cây cảnh BCI 2016Q4

P. 36

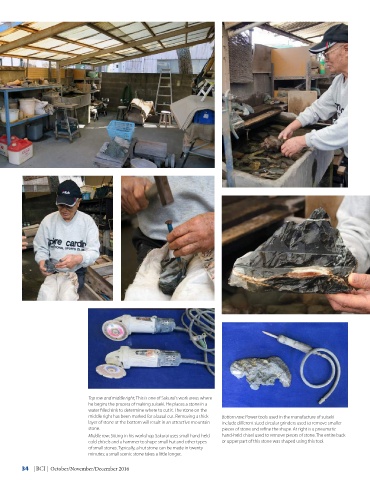

Top row and middle right; This is one of Sakurai’s work areas where

he begins the process of making suiseki. He places a stone in a

water filled sink to determine where to cut it. The stone on the

middle right has been marked for a basal cut. Removing a thick Bottom row; Power tools used in the manufacture of suiseki

layer of stone at the bottom will result in an attractive mountain include different sized circular grinders used to remove smaller

stone. pieces of stone and refine the shape. At right is a pneumatic

Middle row; Sitting in his workshop Sakurai uses small hand held hand-held chisel used to remove pieces of stone. The entire back

cold chisels and a hammer to shape small hut and other types or upper part of this stone was shaped using this tool.

of small stones. Typically, a hut stone can be made in twenty

minutes; a small scenic stone takes a little longer.

34 | BCI | October/November/December 2016